Operation, materials, components.

- Delivery rate: 15 to 290 l/min.

- Max. differential pressure: 120 bar.

- Viscosity: > 1 mm²/s.

- Max. temperature: To 180 °C, magnetic coupling to 300 °C.

- Installation: Wet or dry.

- Spindle housing: Nodular cast iron EN-GJS-400, polymer-coated or other material options.

- Screws: Steel, nitrided.

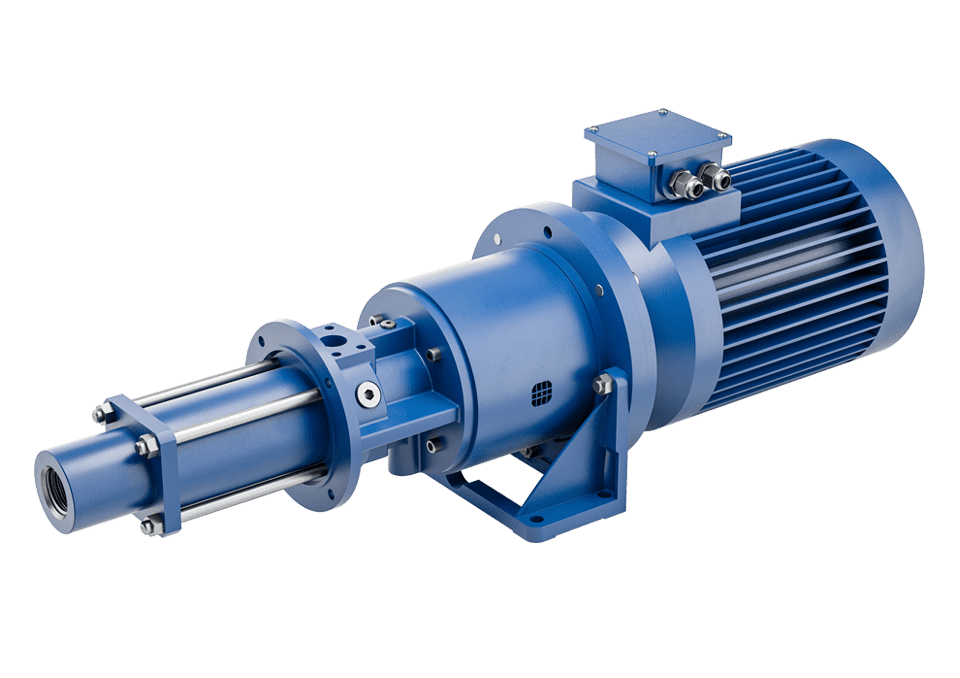

Optimum pump for special requirements.

Pumped fluids such as cooling lubricants are difficult liquids. They contain abrasive dirt, mostly metal residues, and must be pumped at high pressure. In addition, they have a very low viscosity of only about 1 mm²/s.

In the KRAL screw pump of the W series, the screw material and the casing coating have been designed for improved sliding properties in such a way that low viscosity fluids can be pumped with high efficiency.

The running casing is coated with a resistant polymer that can absorb particles. The balancing cylinder of the screw pump has orifice insertions to reduce the leakage rate, therefore efficiency remains high.

KRAL pumps for special requirements.

Compared with other screw pump principles, KRAL screw pumps offer a high flow rate while requiring little space. KRAL pumps deliver continuously and with low pulsation, which protects the pumped media even under difficult conditions.

Installation options.

The KRAL W series screw pump can be designed for dry or wet-well installation. For a vertical wet-well installation, a mounting plate is provided.

Your advantages.

- Resistant, polymer-coated running casing absorbs particles.

- High pressure up to maximum 120 bar at low viscosity.

-

Conveying abrasive liquids.

-

Gentle conveying of the liquid.

- Low pulsation, quiet.

- Multiple installation variations available.

- For many different applications – as you can see in our product catalog or on our website pump overview.

- Technical data.

Technical data 15-26 32-54 55-85 105-118 Qth (1450 min-1, 0 bar) l/min 15-26 32-54 55-85 105-118 Max. pressure at pressure flange bar 120 120 120 120 Temperature max. pumped liquid °C with radial shaft seal NBR 90 90 90 90 with radial shaft seal FKM 150 150 150 150 with mechanical seal standard 150 150 150 150 with mechanical seal hard material 180 180 180 180 with magnetic coupling 300 300 300 300 Viscosity mm²/s min. 1.0 1.0 1.0 1.0 max. 100,000 100,000 100,000 100,000 Max. pressure at suction flange bar with radial sealing ring 6 6 6 6 with mechanical seal standard 6 6 6 6 with mechanical seal hard material 6 6 6 6 with magnetic coupling 6 6 6 6 - Models.

- NPSH.

- Operating instructions.

You have several options for finding the right operating instructions/product information sheet:

- Set filters. Start with the product filter. Confirm the search with SHOW RESULTS.

- Do you know the exact number of the operating instructions/product information sheet? Then enter it in the field No. Document.

- You can also watch the instruction videos.

Search via filter

Full text search

No. Document

Results

No. DocumentProductSeriesSeal/DesignVersionOIK 14OIK 14Screw pumpKMechanical Seal18.04.2024OIK 14 | Screw pump | K | Mechanical Seal

VersionDEENOIK 07OIK 07Screw pumpKRadial shaft seal18.04.2024OIK 07 | Screw pump | K | Radial shaft seal

VersionDEENOIK 09OIK 09Screw pumpKMagnetic coupling18.04.2024OIK 09 | Screw pump | K | Magnetic coupling

VersionDEENOIK 10OIK 10Pump stationEKL/EKS–16.06.2021OIK 10 | Pump station | EKL/EKS | –

VersionDEENOIL 01OIL 01Screw pumpLMechanical seal / Radial Shaft Seal01.06.2024OIL 01 | Screw pump | L | Mechanical seal / Radial Shaft Seal

VersionDEENOIL 02OIL 02Screw pumpLMagnetic coupling01.06.2024OIL 02 | Screw pump | L | Magnetic coupling

VersionDEENOIL 03OIL 03Pump stationELL/ELS–16.06.2021OIL 03 | Pump station | ELL/ELS | –

VersionDEENOIC 01OIC 01Screw pumpCKMechanical seal / Radial Shaft Seal01.06.2024OIC 01 | Screw pump | CK | Mechanical seal / Radial Shaft Seal

VersionDEENOIC 02OIC 02Screw pumpCLMechanical seal / Radial Shaft Seal04.06.2024OIC 02 | Screw pump | CL | Mechanical seal / Radial Shaft Seal

VersionDEENOIC 10OIC 10Screw pumpCGMagnetic coupling18.04.2024OIC 10 | Screw pump | CG | Magnetic coupling

VersionDEENOIC 13OIC 13Screw pumpCLMagnetic coupling04.06.2024OIC 13 | Screw pump | CL | Magnetic coupling

VersionDEENOIC 18OIC 18Screw pumpCGMechanical seal / Radial Shaft Seal18.04.2024OIC 18 | Screw pump | CG | Mechanical seal / Radial Shaft Seal

VersionDEENOIM 01OIM 01Screw pumpMMechanical seal / Radial Shaft Seal01.06.2024OIM 01 | Screw pump | M | Mechanical seal / Radial Shaft Seal

VersionDEENOIM 05OIM 05Screw pumpMMagnetic coupling01.06.2024OIM 05 | Screw pump | M | Magnetic coupling

VersionDEENOIN 04OIN 04Screw pumpNSRadial shaft seal20.04.2020OIN 04 | Screw pump | NS | Radial shaft seal

VersionDEENOIW 01OIW 01Screw pumpWMechanical seal / Radial Shaft Seal19.03.2024OIW 01 | Screw pump | W | Mechanical seal / Radial Shaft Seal

VersionDEENOID 02OID 02Pump stationDKC/DLCMechanical seal / Radial Shaft Seal15.07.2024OID 02 | Pump station | DKC/DLC | Mechanical seal / Radial Shaft Seal

VersionDEENOID 03OID 03Pump stationDKC/DLCMagnetic coupling15.07.2024OID 03 | Pump station | DKC/DLC | Magnetic coupling

VersionDEENOID 05OID 05Pump stationDL2Mechanical seal / Radial Shaft Seal15.07.2024OID 05 | Pump station | DL2 | Mechanical seal / Radial Shaft Seal

VersionDEENOID 06OID 06Pump stationDL3/DL4/DS1/DS3/DS4Mechanical seal / Radial Shaft Seal15.07.2024OID 06 | Pump station | DL3/DL4/DS1/DS3/DS4 | Mechanical seal / Radial Shaft Seal

VersionDEENOID 07OID 07Pump stationDL3/DL4/DS1/DS3/DS4Magnetic coupling15.07.2024OID 07 | Pump station | DL3/DL4/DS1/DS3/DS4 | Magnetic coupling

VersionDEENOIO 08OIO 08FlowmeterOMH–10.04.2024OIO 08 | Flowmeter | OMH | –

VersionDEENOIO 14OIO 14FlowmeterOMG–10.04.2024OIO 14 | Flowmeter | OMG | –

VersionDEENOIO 15OIO 15FlowmeterOME–10.04.2024OIO 15 | Flowmeter | OME | –

VersionDEENOIO 20OIO 20FlowmeterOME compact–10.04.2024OIO 20 | Flowmeter | OME compact | –

VersionDEENOIO 23OIO 23FlowmeterOMP–31.05.2023OIO 23 | Flowmeter | OMP | –

VersionDEENOIO 28OIO 28FlowmeterOMX–30.04.2022OIO 28 | Flowmeter | OMX | –

VersionDEENOIO 30OIO 30FlowmeterOMSLow-viscosity liquids10.04.2024OIO 30 | Flowmeter | OMS | Low-viscosity liquids

VersionDEENOIO 31OIO 31FlowmeterOMSHigh-viscosity liquids29.03.2024OIO 31 | Flowmeter | OMS | High-viscosity liquids

VersionDEENOIO 03OIO 03FlowmeterOMK–10.04.2024OIO 03 | Flowmeter | OMK | –

VersionDEENOIE 26OIE 26ElektronicsBEM 100–22.06.2020OIE 26 | Elektronics | BEM 100 | –

VersionDEENOIE 29OIE 29ElektronicsBEM 100Support-Software Smart Support22.04.2020OIE 29 | Elektronics | BEM 100 | Support-Software Smart Support

VersionDEENOIE 29OIE 29ElektronicsBEM 150Support-Software Smart Support21.04.2020OIE 29 | Elektronics | BEM 150 | Support-Software Smart Support

VersionDEENOIE 27OIE 27ElektronicsBEM 150–30.06.2022OIE 27 | Elektronics | BEM 150 | –

VersionDEENOIE 24OIE 24ElektronicsBEM 200–21.02.2024OIE 24 | Elektronics | BEM 200 | –

VersionDEENOIE 15OIE 15ElektronicsBEM 300–07.10.2021OIE 15 | Elektronics | BEM 300 | –

VersionDEENOIE 23OIE 23ElektronicsBEM 300Modbus communication30.05.2012OIE 23 | Elektronics | BEM 300 | Modbus communication

VersionDEENOIE 22OIE 22ElektronicsBEM 500Modbus communication30.07.2019OIE 22 | Elektronics | BEM 500 | Modbus communication

VersionDEENOIV 01OIV 01ElektronicsBEM 500Differential measurement10.12.2019OIV 01 | Elektronics | BEM 500 | Differential measurement

VersionDEENOIE 12OIE 12ElektronicsBEM 500–05.10.2021OIE 12 | Elektronics | BEM 500 | –

VersionDEENOIE 30OIE 30ElektronicsSmart Solution Display–21.05.2024OIE 30 | Elektronics | Smart Solution Display | –

VersionDEENOII 08OII 08SensorsEETTemperatur sensors30.07.2021OII 08 | Sensors | EET | Temperatur sensors

VersionDEENOII 02OII 02SensorsBEGPick up09.01.2024OII 02 | Sensors | BEG | Pick up

VersionDEENOIG 01OIG 01Screw pumpGMechanical Seal21.12.2023OIG 01 | Screw pump | G | Mechanical Seal

VersionDEENOPR 01OPR 01Screw pumpKProduct information sheet30.09.2021OPR 01 | Screw pump | K | Product information sheet

VersionDEENOPR 02OPR 02Screw pumpKProduct information sheet30.09.2021OPR 02 | Screw pump | K | Product information sheet

VersionDEENOPR 03OPR 03Screw pumpKProduct information sheet30.09.2021OPR 03 | Screw pump | K | Product information sheet

VersionDEENOPR 04OPR 04Screw pumpKProduct information sheet30.09.2021OPR 04 | Screw pump | K | Product information sheet

VersionDEENOPR 07OPR 07Screw pumpLProduct information sheet21.12.2023OPR 07 | Screw pump | L | Product information sheet

VersionDEENOPR 05OPR 05Screw pumpKProduct information sheet21.12.2023OPR 05 | Screw pump | K | Product information sheet

VersionDEENOPR 06OPR 06Screw pumpKProduct information sheet21.12.2023OPR 06 | Screw pump | K | Product information sheet

VersionDEENOPR 08OPR 08Screw pumpLProduct information sheet21.12.2023OPR 08 | Screw pump | L | Product information sheet

VersionDEENOPR 09OPR 09Screw pumpCKProduct information sheet21.12.2023OPR 09 | Screw pump | CK | Product information sheet

VersionDEENOPR 10OPR 10Screw pumpLProduct information sheet21.12.2023OPR 10 | Screw pump | L | Product information sheet

VersionDEENOPR 11OPR 11Pump stationDKC/DLCProduct information sheet21.12.2023OPR 11 | Pump station | DKC/DLC | Product information sheet

VersionDEENOPW 01OPW 01Screw pumpKProduct information sheet01.09.2021OPW 01 | Screw pump | K | Product information sheet

VersionDEENOPW 02OPW 02Screw pumpKProduct information sheet01.09.2021OPW 02 | Screw pump | K | Product information sheet

VersionDEENOPW 03OPW 03Screw pumpKProduct information sheet01.09.2021OPW 03 | Screw pump | K | Product information sheet

VersionDEENOPW 04OPW 04Screw pumpKProduct information sheet01.09.2021OPW 04 | Screw pump | K | Product information sheet

VersionDEENOPW 09OPW 09Screw pumpKProduct information sheet01.09.2021OPW 09 | Screw pump | K | Product information sheet

VersionDEENOPW 10OPW 10Screw pumpKProduct information sheet01.09.2021OPW 10 | Screw pump | K | Product information sheet

VersionDEENOPW 11OPW 11Screw pumpKProduct information sheet01.09.2021OPW 11 | Screw pump | K | Product information sheet

VersionDEENOPW 12OPW 12Screw pumpKProduct information sheet01.09.2013OPW 12 | Screw pump | K | Product information sheet

VersionDEENOPW 13OPW 13Screw pumpKProduct information sheet01.09.2021OPW 13 | Screw pump | K | Product information sheet

VersionDEENOPW 15OPW 15Screw pumpKProduct information sheet01.09.2021OPW 15 | Screw pump | K | Product information sheet

VersionDEENOPW 16OPW 16Screw pumpKProduct information sheet21.12.2023OPW 16 | Screw pump | K | Product information sheet

VersionDEENOPW 17OPW 17Screw pumpKProduct information sheet01.09.2021OPW 17 | Screw pump | K | Product information sheet

VersionDEENOPW 18OPW 18Screw pumpKProduct information sheet01.09.2021OPW 18 | Screw pump | K | Product information sheet

VersionDEENOPW 19OPW 19Screw pumpKProduct information sheet01.09.2021OPW 19 | Screw pump | K | Product information sheet

VersionDEENOPW 20OPW 20Screw pumpKProduct information sheet21.12.2023OPW 20 | Screw pump | K | Product information sheet

VersionDEENOPW 21OPW 21Screw pumpLProduct information sheet21.12.2023OPW 21 | Screw pump | L | Product information sheet

VersionDEENOPW 22OPW 22Screw pumpLProduct information sheet21.12.2023OPW 22 | Screw pump | L | Product information sheet

VersionDEENOPW 25OPW 25Pump stationDKC/DLCProduct information sheet01.09.2013OPW 25 | Pump station | DKC/DLC | Product information sheet

VersionDEENOPW 27OPW 27Screw pumpMProduct information sheet01.03.2014OPW 27 | Screw pump | M | Product information sheet

VersionDEENOPW 28OPW 28Screw pumpMProduct information sheet01.03.2014OPW 28 | Screw pump | M | Product information sheet

VersionDEENOPW 29OPW 29Screw pumpMProduct information sheet01.03.2013OPW 29 | Screw pump | M | Product information sheet

VersionDEENOPW 30OPW 30Screw pumpMProduct information sheet01.03.2014OPW 30 | Screw pump | M | Product information sheet

VersionDEENOPW 31OPW 31Screw pumpMProduct information sheet01.03.2014OPW 31 | Screw pump | M | Product information sheet

VersionDEENOPW 32OPW 32Pump stationDML/DMS

MProduct information sheet01.10.2014OPW 32 | Pump station | DML/DMS | Product information sheet

VersionDEENOPW 34OPW 34Screw pumpLProduct information sheet21.12.2023OPW 34 | Screw pump | L | Product information sheet

VersionDEENOPW 35OPW 35Screw pumpLProduct information sheet21.12.2023OPW 35 | Screw pump | L | Product information sheet

VersionDEENOPW 36OPW 36Screw pumpCKProduct information sheet21.12.2023OPW 36 | Screw pump | CK | Product information sheet

VersionDEENOPW 39OPW 39Screw pumpLProduct information sheet21.12.2023OPW 39 | Screw pump | L | Product information sheet

VersionDEENOPW 40OPW 40Pump stationDKC/DLCProduct information sheet01.10.2014OPW 40 | Pump station | DKC/DLC | Product information sheet

VersionDEENOPW 41OPW 41Pump stationDKC/DLCProduct information sheet21.12.2023OPW 41 | Pump station | DKC/DLC | Product information sheet

VersionDEENOPW 48_RROPW 48_RRScrew pumpCLProduct information sheet01.09.2017OPW 48_RR | Screw pump | CL | Product information sheet

VersionDEENOPW 49_RROPW 49_RRScrew pumpCLProduct information sheet01.04.2018OPW 49_RR | Screw pump | CL | Product information sheet

VersionDEENOPW 51OPW 51Screw pumpWProduct information sheet21.12.2023OPW 51 | Screw pump | W | Product information sheet

VersionDEENOIR 01OIR 01Screw pumpRMechanical Seal01.09.2022OIR 01 | Screw pump | R | Mechanical Seal

VersionDEENOIR 02OIR 02Screw pumpRMagnetic coupling30.09.2022OIR 02 | Screw pump | R | Magnetic coupling

VersionDEENOPW 33OPW 33Screw pumpRProduct information sheet21.12.2023OPW 33 | Screw pump | R | Product information sheet

VersionDEENOPW 42OPW 42Screw pumpRProduct information sheet21.12.2023OPW 42 | Screw pump | R | Product information sheet

VersionDEENOPR 12OPR 12Screw pumpRProduct information sheet21.12.2023OPR 12 | Screw pump | R | Product information sheet

VersionDEENOPW 56OPW 56Screw pumpGProduct information sheet22.04.2024OPW 56 | Screw pump | G | Product information sheet

VersionDEENOPW 37OPW 37Pump stationDKC/DLCProduct information sheet21.12.2023OPW 37 | Pump station | DKC/DLC | Product information sheet

VersionDEENOPW 38OPW 38Pump stationDKC/DLCProduct information sheet21.12.2023OPW 38 | Pump station | DKC/DLC | Product information sheet

VersionDEENOIW 02OIW 02Screw pumpWMagnetic coupling19.03.2024OIW 02 | Screw pump | W | Magnetic coupling

VersionDEENOIX 01OIX 01-01Pump stationDKC/DLCATEX supplementary instructions manuel zones 1/2 and 21/2201.12.2022OIX 01-01

VersionDEENOIX 02OIX 02FlowmeterOMH

OMG

OME

OMP

OMXATEX supplementary instructions manual30.01.2018OIX 02

VersionDEENOIX 01OIX 01-02Screw pumpCG

CK

CL

K

L

M

WATEX supplementary instructions manuel zones 1/2 and 21/2201.12.2022OIX 01-02

VersionDEENOIX 05OIX 05-01Pump stationDKC/DLC

DL3/DL4/DS1/DS3/DS4ATEX supplementary instructions manuel zones 2 and 2218.07.2023OIX 05-01

VersionDEENOIX 05OIX 05-02Screw pumpCG

CK

CL

G

K

L

M

WATEX supplementary instructions manuel zones 2 and 2218.07.2023OIX 05-02

VersionDEEN

![[Translate to Englisch:] flange_screw_pumps_universal_horizontal.jpg Flange screw pumps universal for horizontal installation](/fileadmin/_processed_/9/6/csm_baureihe-w-bauform-w_09ad02e33c.png)

![[Translate to Englisch:] screw_pumps_in_tank_pump_vertical_W.jpg In tank screw pumps w series vertical position](/fileadmin/_processed_/5/0/csm_baureihe-w-bauform-w-tank_bf2c744e06.png)